Welcome to our website

Welcome to our website

Welcome to our website

Welcome to our website

FEATURES

1. The powder granulating can improve the liquidity and reduce dust;

2. The powder granulating can improve the solubility;

3. Mixing, granulating, and drying can be done by the same machine(one step granulation);

4. Use electrostatic to filter materials, safe working condition;

5. The atomizer for adhesive adapts multiple spray lances, the particle is uniform and the qualified rate of finished product is high;

6. There is no dead corner in granulator so the feeding and discharging is quick and convenience.

APPLICATION

GRANULATING AND COATING

Medicine

- Granulating: Tablet Granule, Quick Solved Granule, Granule Capsule

-Coating: Granule, Pill Protection, Formulated Color, Slow Release, Film, Enteric

Foodstuff

- Sugar, Coffee, Cocoa Powder, Cream, Powder Syrup, Amino Acid, Seasonings, Puffed Food

GRANULATING

- Pesticide, Pigment, Dyestuff

DRYING

- Powder, Granule, Block Materials

Characteristics

◎Because of powder granulating, the fluidity can be improved and the powder dust can be reduced;

◎Because of powder granulating, the solubility is improved;

◎The procedures of mixing, granulating and drying can be finished in one step(granulating through one step);

◎Because the atomizer for adhesive adapts multi-fiuid spray lance, the particle is uniform and the percent of pass of finished products is raised greatly;

◎There is no dead corner in equipment. It is quick and convenient to feeding and discharge;

◎The equipment is clean through washing.

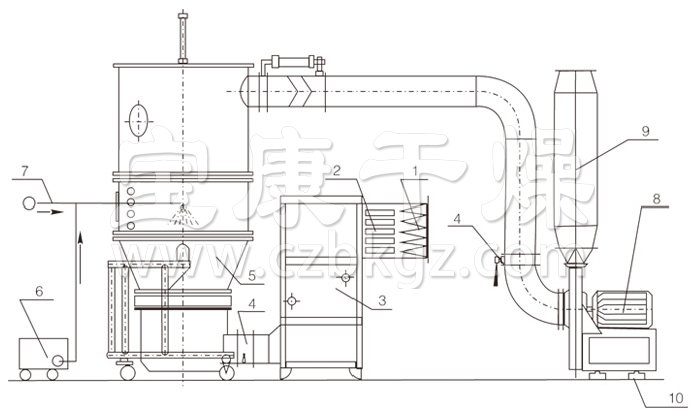

PRODUCTION FLOWCHART

1. Mid-effect filter 2. Postfilter 3. Heater 4. Distributor 5. Fluldized bed 6. Liquid feeding pump 7. Compressed air 8. Vacuum fan 9. Silencer 10. Vibration eliminator

Technical Parameter

| Specification | 3 | 5 | 15 | 30 | 45 | 60 | 90 | 120 | 150 | 200 | 300 | 500 |

| Volume (L) | 12 | 22 | 45 | 100 | 155 | 220 | 300 | 420 | 530 | 660 | 1000 | 1500 |

| Amount to be treated (kg/per time) | 1.5/4.5 | 4/6 | 10/20 | 15/45 | 25/65 | 40/80 | 60/120 | 80/160 | 90/200 | 100/300 | 150/450 | 300/300 |

| Power of fan (kw) | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 18.5 | 22 | 30 | 37 |

| Consume of steam 0.4MPa (kg/h) | 12 | 23 | 42 | 70 | 99 | 141 | 169 | 211 | 251 | 282 | 366 | 451 |

| Consume of compressed air (m3/min) | 0.3 | 1.3 | 0.3 | 0.4 | 0.4 | 0.6 | 0.6 | 0.9 | 0.9 | 0.9 | 1.3 | 1.5 |

| Noise,db (A) | (fan is installedseparately)≤75 | |||||||||||

| Overall dimension (m) |

1.0x |

1.2x |

1.25x |

1.6x |

1.65x |

1.85x |

1.85x |

2.2x |

2.27x |

2.34x |

2.8x |

3x |

Note: Model FG can not be equipped with granulating part.